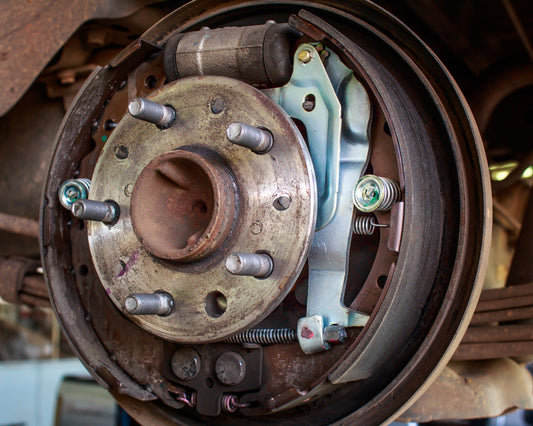

Problem: Rear brake sensitivity, lock-up and hydraulic failure

Cause: Clip design of certain GM wheel cylinders allows for the wheel cylinder to rotate. This rotation can cause rear brake sensitivity problems and eventually allow the wheel cylinder to rotate to a point where the piston is no longer against the brake shoe. This allows the piston to be pushed out of the wheel cylinder bore which causes hydraulic failure.

Solution: Checking the GM Clip In Style Wheel Cylinder

It is critical to check for excessive looseness in this type of wheel cylinder/ backing plate arrangement. Follow the procedures below to check the GM clip in style wheel cylinder:

1. Start with a visual inspection of the wheel cylinder. It should be in a horizontal position in reference to the backing plate. If the wheel cylinder is at an angle the backing plate is probably worn.

2. Even if the wheel cylinder is properly aligned (horizontal) perform this check. Attempt to rotate the wheel cylinder in the backing plate. Only the slightest movement should be felt (If any). If the wheel cylinder rocks in the backing plate excessive wear has taken place and the wheel cylinder and backing plate should be serviced.

NOTE: Failure to service the wheel cylinder and backing plate when this condition is present can lead to rear brake failure.

Figure 63.1

Figure 63.1  Figure 63.2

Figure 63.2 Figure 63.3

Figure 63.3  Figure 63.4

Figure 63.4