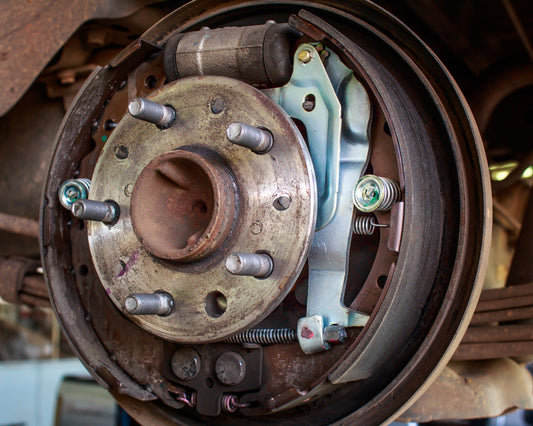

Problem: Intermittent low brake pedal on vehicles equipped with Delco VI ABS (see figure 46.1)

Cause: EMB (electromagnetic brake) or ESB (expansion spring brake) not holding the motor in homed position. See more info section.

Solution: This condition is usually not straightforward to diagnose. The primary reason for this is its intermittent nature. The most effective method of diagnosing it will be to look for supporting symptoms of the condition. The symptoms that will support the EMB or ESB as the cause of the low pedal will be:

- ABS light on with either a code 38 (left front), code 41 (right front), or a code 42 (rear brake circuit).

- The problem occurs only ONCE per drive cycle.

- The occurrence of the issue should be in time with the ABS light coming on.

- There should be an underhood noise associated with the event as the piston causes the gears to the wind.

- If you can duplicate the problem with each pump of the brake pedal or more than once without resetting the ABS, the problem is the master cylinder.

- If the problem occurs without a code, noise from the modulator/ motor pack, the problem is the master cylinder.

More Info

ABS failures rarely cause conventional brake problems, but it is wise to be aware of those that can. The lack of this knowledge can lead to many hours of wasted effort and frustration. While most technicians are familiar with the RWAL/RABS dump valve causing excessive pedal travel, few are aware of a similar problem with the Delco VI. The Delco VI is the most common ABS in use today based on the number of units in the field. It is also unique in how it modulates the brake pressure during an ABS stop. Instead of solenoid sets and a pump motor assembly, the Delco VI uses motor-driven pistons (Figure 46.2).The pistons are driven up and down by high-speed bidirectional motors to modulate the brake pressure during an ABS stop. During standard braking, the pistons are held in their uppermost or “homed” position by two types of motor brake assemblies. The motor brakes prevent the pressure in the system from pushing the pistons down during standard braking.

The most common type of motor brake is known as the expansion spring brake. As shown in Figure 46.3., this type is located at the base of the motor. The expansion spring prevents the large gear on the base of the piston/worm gear assembly from spinning the small motor gear but allows the motor to drive the small gear in either direction.

Electromagnetic Motors

Some Delco VI units utilize an electromagnetic motor brake, as shown in Figure 46.4. This design uses three small brake pads in a tripod holder:

- The holder is attached to the top of the motor shaft.

- Brake pads clamped between a base plate.

- And a spring-loaded upper plate.

If any of the three motor brakes fail, it will not maintain the piston in its homed position. The pressure generated from standard braking will drive the piston down in its bore, as shown in Figure 46.5. The extra fluid volume needed to fill this space will cause the brake pedal to travel to the floor, acting as a master cylinder problem.There will be some noticeable differences when this failure occurs when compared to a bypassing cup seal. The first thing that should happen is the ABS light should come on. The Delco VI will trigger a code 38 for the left front motor brake, code 41 for the right front, and code 42 for the rear. The second thing that you should notice is the problem will happen only once per drive cycle. Once the piston is in the down position and the code has been triggered, the ABS shuts down. The brakes will be regular until the process of the ignition begins again and the vehicle self-tests. When this occurs, the EBCM will drive the pistons to their homed position.

Looking for Symptoms

Newer systems will self-test without driving the vehicle, while older ones require a test drive above four mph. Once the self-test occurs, the problem can reoccur. One last thing that will help differentiate this problem from that of a failed master cylinder. The Delco VI is a loud system when it operates. If a motor brake fails and the pressure pushes down the piston, it will produce a pronounced noise from the modulator/ motor pack assembly. You will hear the piston and motor gear winding. In class, I hot wire the EMB and duplicate this problem to demonstrate it to the students. You can’t miss it. So before you perform some of the involved procedures published, look for these symptoms. Assuming the line lock test is pointing you to the master cylinder/modulator, then inbasic terms:

- If you can duplicate the problem with each pump of the brake pedal or more than once without resetting the ABS, the problem is the master cylinder.

- If the problem occurs without a code, noise from the modulator/ motor pack, the problem is the master cylinder.

More Tips and Tricks

Want more tips and tricks? Consider joining our Facebook page or reading more articles by selecting one of the buttons below:

Facebook Group

More Articles