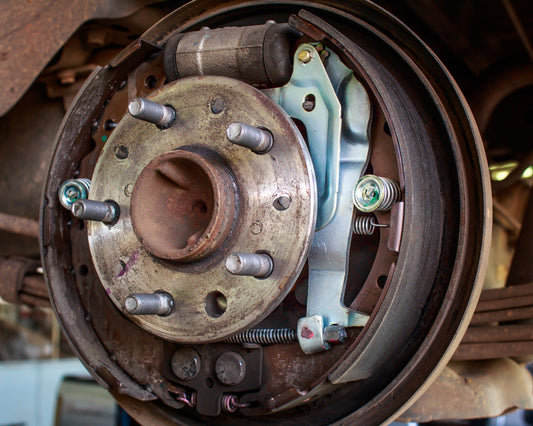

If you have ever wondered how to lubricate brakes, look no further than this month’s Tech Tricks Tuesday as that is what we will be covering.

The terms brakes and lubrication at first glance may not seem to go together but they really do. Lubrication of brake components where there is metal-to-metal contact points is critical. Failure to have these points lubricated, with the proper type of lubrication, can be the cause of noise, brake pad or shoe restricted movement, irregular pad or shoe wear, chattering and other brake issues and problems. The brand of brake lubrication you use on the metal-to-metal contact points is not as important as the specifications of the product. It must be a brake lubricant listed for brake components, specifically metal to metal contact points.

This information block covers only metal to metal brake contact service points. Caliper guide pins which are usually a metal pin and an EDPM busing or O-ring will be covered in a different web presentation.

Step 1

If this brake assembly were inspected in a shop, most techs would be concerned about the pad thickness and little else. Pad thickness is important in a brake inspection but so is proper caliper and pad movement.

Step 2

The pads on this vehicle still have a large percentage of their life left but the amount of corrosion on the sliding pad and caliper components is restricting brake operation. (Note: When tested on a dynamic drive on brake tester, a 15% decrease in this wheels brake operation was documented). Look at the rust and scale at the pad ears to bracket mounting points.

Step 3

Some techs choose to lubricate the pad backing to caliper piston or pad backing to outer pad caliper bracket area and some don’t. It’s a matter of personal choice.

Step 4

Failure to lubricate the pad backing plate ears will lead to restricted movement and possibly tapered or irregular pad wear.

Step 5

This pads contact tension arm is another mandatory lubrication point as it is a metal to metal contact point (the arm to the caliper bracket).

Step 6

Lubrication must be used sparingly and sensibly. This is an example of excessive lubrication. About 1/3 or less of the amount of lubrication shown would have done the job.

Step 7

Even though contact points are properly lubricated they may not be the source of noise. Pad ears to bracket excessive movement because of excessive wear can be eliminated by shims supplied by the pad manufacture. If when installed the pad has excessive movement when apply hand pressure there is frequently a solution.

We will have more of the story on how to lubricate brakes next week for Tech Tricks Tuesday.

You can also follow us on Social Media to know more of what we are up to and to get even more tips and tricks.