This week we will be covering part 4 to our brake lubrication blog posts. You can read the other three parts on our Blog.

Step 21

The normal amount of movement between the pads shim and caliper piston will accelerate and wear and corrosion that occurs. Many feel the contact point between the caliper pistons pad contact area and the pad/shim should be lubricated.

Step 22

Note that the shim where it contacts the outer caliper bracket ears is partially eaten through from corrosion. Also not the amount of rust flaking present on the system. Most likely the outer pad is restricted in its movement by the corrosion and flaking. Outer pad restricted movement usually causes taper outer pad wear.

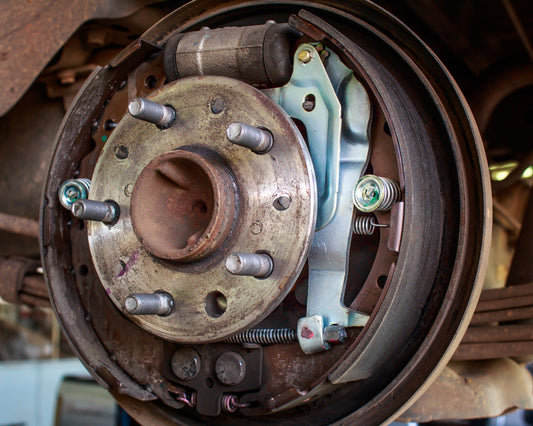

Step 23

The bellows seal for the caliper mounting pin looks ok and the caliper pin will most likely allow normal caliper sliding movement but the rust and corrosion on the pad mounting ear area will restrict pad movement. All areas of a sliding caliper must allow the caliper and pads to move freely during brake operation.

Step 24

Draw filing is one of the best ways to clean up a caliper mounting brackets pad contact area. By using a file you prevent any possible grooving or unparalleled alignment of the pad ear areas which can occur is you use a small disc sander.

Step 25

Whenever doing brake reline work use new abutment or pad ear contact shims. The old shims get rusted, lose their tension and may not hold the pad in its correct alignment after many miles of service.

Step 26

This assembly was inspected and re-lubricated then returned to service. In some parts of the country this type of service may be needed every year or two if the winter is harsh and the salt usage or de-icing liquid usage is high.

This post concludes our October edition of our Tech Tricks Tuesday. In November, we will be discussing BrakeStrip in a little more detail than we have before. Stay tuned and come back.

You can also follow us on Social Media to know more of what we are up to and to get even more tips and tricks.