How to Remove a Rusted Bleeder Screw

If someone says "Pin It", you may think of a web site that folks sell things on. Nothing could be farther from the truth for our meaning of the term "Pin It".What we are talking about is "pinning" or filling the hollow center of a brake bleeder valve when removing it. Why would you want to do this? The answer is simple. This is done to help keep the rusted bleeder screw from breaking when it is "frozen" in the caliper and you are trying to loosen or remove it.

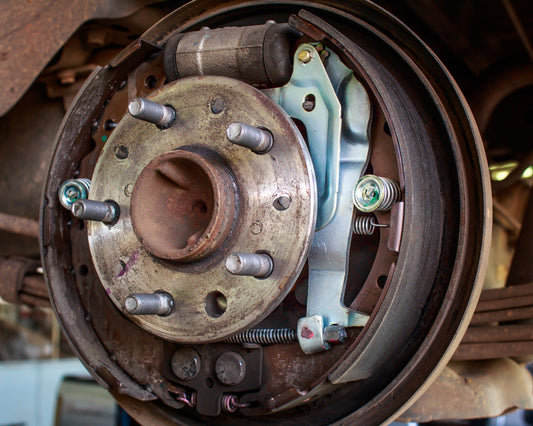

Image 1

Image 1Image 1

If you take a straw, hold one end, and twist the other end of the straw the center of the straw will twist around itself. Think of a hollow bleeder valve with the bottom of the bleeder valve rusted into the caliper. Think of what happens to the bleeder valve when you apply force with a wrench trying to loosen it.

Image 2

Image 2

Prevent Future Rusted Bleed Screws with the Phoenix Systems USA Made bleed screw caps.

Click Here to Learn More about the bleeder caps

Image 2

Now fill the straw with sand or water and repeat this twisting test. You will find that the entire straw now moves. In other words, the straw doesn't collapse inward onto itself. Pinning a hollow bleeder valve creates the same effect.

Image 3

Image 3Image 3

Note the amount of rust and scale on the bottom seat area of this bleeder. Bleeder valves freeze up not only on their threaded area but also on the tapered seat at the bottom of the valve.

Image 4

Image 4Image 4

As mentioned, this is what usually happens to a frozen bleeder valve when it is attempted to be removed. First, the hex flats stripped off then when a locking pliers was used the bleeder collapsed inward on itself breaking in two. The result required caliper replacement to handle the problem.

Image 5

Image 5Image 5

You can use most anything to fill the center hold of a bleeder valve but a piece of soft welding rod (aluminum welding rod) works very well. Cut the piece slightly longer than the hollow center length.

Image 6

Image 6Image 6

Insert the "pin" into the bleeders center and tap it downward as far as possible. Don't worry if it's a bit long. The idea is to fill the center completely. The soft welding rod will simply flatten itself onto the end of the valve.

Image 7

Image 7Image 7

Obtain a Phoenix Systems "Brake Free" air hammer tool and place a socket on it of the correct size to fit the bleeder valve. Note: If you use a shallow socket you will apply more force onto the frozen threads and seat than with a deep socket.

Image 8

Image 8

Free any rusted or frozen bleed screw with Phoenix Systems USA Made BrakeFree Tool

Click Here to Learn More about the BrakeFree Tool.

Image 8

With the "Brake Free" tool connected to an air hammer insert a #2 Phillips screwdriver or other similar tool through the hole of the "Brake Free" tool. Push downward firmly on the air hammer while pulling the trigger of the air hammer and apply left hand rotational force to the "Brake Free" blade through the Phillips screwdriver.

Image 9

Image 9Image 9

If you use heat to try to free up the bleeder valve the heat will travel into the caliper body itself and will reach the area housing the caliper square cut seal. This heat may easily cause the seal to have problems. It is never a good idea to heat a bleeder valve to try and free it up. Don't do it. The negative effects can be safety related.

By using a "BrakeFree" tool along with a good air hammer and a #2 Phillips or other similar drift along with "Pinning" a bleeder screw before applying any force to it, you will find that you will be successful in removing most frozen bleeders.

Granted, you will have to replace the bleeder as it's almost impossible to get the pin out but that is a small price to pay for successfully remove a frozen bleeder rather than having to replace the entire caliper. We hope that you enjoyed our post on how to remove a rusted bleeder screw.

The "Brake Free" tool can be ordered on our website in our Specialty Tool section.

Prevent Future Rusted Bleed Screws with the Phoenix Systems USA Made bleed screw caps.

Click Here to Learn More about the bleeder caps