I hope you all had a safe and enjoyable Labor Day weekend. We are in a new month, which means a new topic for Tech Tricks Tuesday. This month we will be tackling Relining Front Disc Brakes and Rotor Service. I hope that you find this Blog informative and helpful.

After you have inspected a vehicle and determined what is needed the next step is to replace the worn parts and service the system as required. Over the next month we will cover “disc pad replacement/rotor service” procedure on the 2004 Toyota Tacoma truck shown in the previous inspection sections.

Step 1

No matter how old and tired a vehicle looks, go by what you found during a brake inspection and not by a judgment call from how the vehicle looks.

Step 2

While technically not part of relining the front brakes, the fluid level in a master cylinder should always be checked whenever doing any brake service. If it hasn’t been checked and fluid added for some time, it may be low because of the outward movement of the caliper pistons when the pads wear.

Step 3

Don’t just take off the wheels. Unless you are also rotating the tires, mark a wheel lug hole to a stud and return it to that position when reinstalling. It may not be a big deal but then again it may have been matched mounted to eliminate a vibration issue. Why chance it?

Step 4

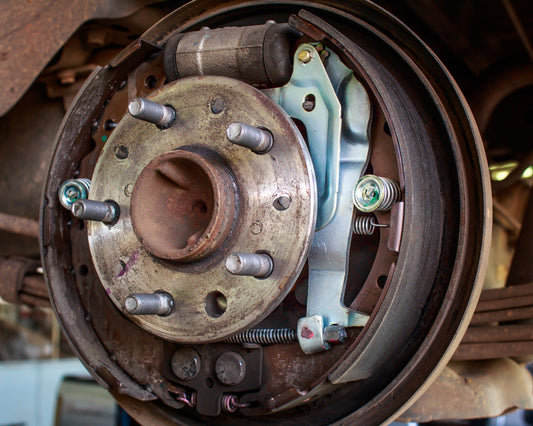

The appearance of this rotor is completely normal. The brakes on this truck have over 135,000 miles on them and what you are seeing is the transfer layer of material from the pads. When new pads are installed, the rotors should be turned so a new transfer layer of material from the new pads can be established. Using new pads on non-turned rotors with a transfer layer on them may cause noise or altered braking.

Step 5

Removing the caliper mounting bolts is the first step in the disassembly process. After removing the caliper mounting bolts, inspect them immediately for corrosion, contact wear or any other condition that would indicate that replacement would be necessary.

Step 6

Without exception, always hang or support the removed caliper by some approved method. Do not simply place it on top of the control arm or another location and hope that it will remain there during brake service. Most likely it will not.

Step 7

When you remove the old pads sight down the friction edge looking for uniform thickness or taper wear. If you have a used pad with taper wear, you have a caliper slide issue. Pay close attention as if there is taper wear, you must locate the cause and correct it when relining the brakes.

Step 8

When doing the next step of removing the caliper mounting bracket, first try a box end wrench. Because of their location it’s frequently very difficult to use an impact with a socket to loosen them.

Step 9

Once you have loosened the caliper bracket bolts, use a ratcheting box end wrench to remove them. This will save you a lot of time. Don’t try to initially loosen the bolts with the type of wrench shown. It just doesn’t have the heft to initially loosen these very tight bolts.

We will have more of the story on how to properly reline front disc brakes and perform a rotor service next week for Tech Tricks Tuesday.

You can also follow us on Social Media to know more of what we are up to and to get even more tips and tricks.