- Rotor has runout

- Hub has runout

- Hub to motor mating surface is not clean

Rotor to Hub Index

The following steps will go over the indexing process. Following these steps will help you find the issue and, in most cases, fix it as well. To get started, follow the steps below to index the rotor to the hub.

1. Measure rotor runout

2. If runout is greater than the allowable specification (usually no more than .002") then proceed to the next step.

3. Index the rotor to a wheel stud.

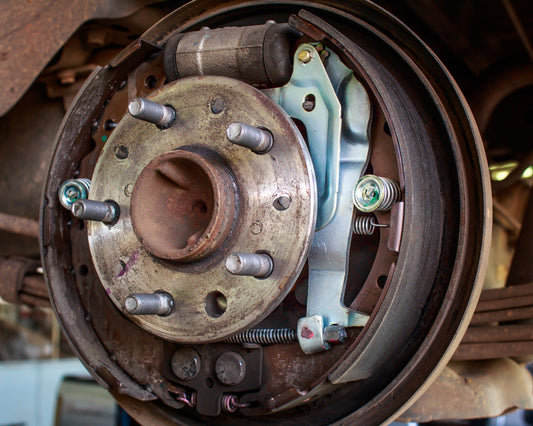

4. Rotate rotor until the dial indicator reading is at its highest value. Use a magic marker to mark this point on the rotor and hub flange as shown in the image below:

5. Next, remove the rotor. Check the hub and rotor mating surface for dislodged rust or anything else that could cause the runout. If the mating surface is good install the rotor by rotating it 2 lug positions from its original position.

6. Finally, Measure the runout. If it is now within the specifications, proceed to the next wheel. If not, rotate the rotor until the dial indicator reading is at its highest value. Continue by checking the position of the marks on the rotor and hub in relation to the high spot. If the high spot aligns with the rotor, the rotor is the source of the runout. If the high spot aligns with the mark on the hub, then the hub has runout.

More Help

Looking for more mechanical help? Consider joining our Facebook group "Mechanic Mafia". The group is a great place for mechanics from all skill levels to interact, rant, and share experiences. Just click the button below to join today. Otherwise, feel free to check out some of our other tech tips by clicking "more articles" below.Facebook Group

More Articles