Problem

Determining when and why to add the proportioning valves to the possible causes of the problem being diagnosed.

Cause

Not understanding the proportioning valve can result in the valve being added to the list of possible cases when it cannot cause the diagnosed problem or add it to the list when it should be.

Solution

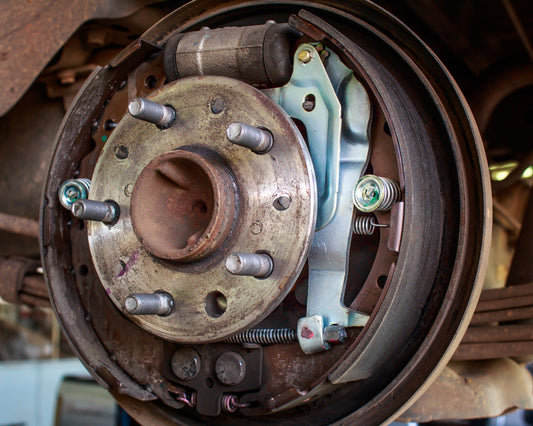

The proportioning valve is there to prevent rear-wheel lockup during panic braking. Its two main reasons are 1. most vehicles use drum brakes in the rear, and 2. all vehicles experience weight transfer during a panic stop. Rear drum brakes are hydraulic over mechanical in design.

If applying too much pressure to the wheel cylinders, lockup will occur. All vehicles with rear drum and rear disc brakes will experience weight transfer during a panic stop. When taking off the rear wheels' weight during a panic stop, the tendency for the rear brakes to lock up will increase. The design of the proportioning valve is there to limit the pressure to the rear brakes during a panic braking situation.

When do proportioning valves work?

The most crucial point to understand about proportioning valves is when they work – only during panic braking. This means that a vehicle could potentially go its whole life without ever using its proportioning valve. Located between the master cylinder and rear brakes, the conventional proportioning valves are hydraulically activated.

Vehicles with front-to-back split hydraulic systems have one, while diagonal splits systems require two because each rear wheel is on a separate hydraulic circuit. The proportioning valve may be a stand-alone valve, part of the combination valve, or built into the master cylinder.

Deeper Inspection

Whether or not you take the additional steps to inspect or diagnose a vehicle’s hydraulic proportioning valve will depend on the following:

- Could the customer’s complaint involve the proportioning valve?

- What is the condition and location of the combination valve?

- What type of proportioning valve does the vehicle have?

Proportioning Valve Cap Screw

The design of some proportioning valves allows two things – more chance for failure and an easy way to diagnose them. If we look at the proportioning valve in Figure 49.1, we will see the cap screw that holds the piston and spring in place is vented.The vent hole is a small rubber “mushroom” that prevents moisture from entering the cap screw. If this valve style is mounted low on the vehicle, as in most rear-wheel drive vehicles, it can introduce a high degree of moisture.This is especially true in areas that use road salts for snow and ice removal. The moisture can corrode the cap screw and allow water to enter into where the piston travels in the cap screw (See Figure 49.2). This causes the cap screw to rust, which bonds the piston and cap screw together (See Figure 49.3).Typically after removing the cap screw, the cap screw, spring, and piston are separate pieces. This corrosion prevents the piston from moving when a panic braking situation occurs.

49.1

49.2

49.3

Checking the Proportioning Valves

The same thing that allows the valve to fail will enable us to check it – the cap screw vent hole. First, determine if the valve is a good candidate by its external appearance. If corrosion occurs outside the valve or the cap screw, it is a good candidate. Remove the rubber mushroom from the cap screw.Next, insert a paper clip to the bottoms out of the piston, as in Figure 49.4. Have an assistant start the vehicle and apply heavy pedal pressure to simulate a panic braking situation. The paper clip should push against you and travel about 1/32” to 1/16” as the piston moves. If the paper clip doesn’t move, the piston has seized in the cap screw, and the valve will need replacing. This test will work on any proportioning valve vented through the cap screw and should be part of your standard inspection if the valve’s exterior condition merits it.

Checking the Proportioning Valves (Not Vented)

Many proportioning valves are not vented through the cap screw. There is not a quick check for these types of valves. These valves should only be checked if the customer’s complaint indicates a possible proportioning valve problem. Most shops do not have pressure gauges, so diagnosing the issue will have to be eliminated. You should check all other possible causes before condemning the proportioning valve.Pressure gauges are the best way to diagnose a failed proportioning valve. There will be a gage installed into the front and rear hydraulic circuits. Start the vehicle, and apply the brake pedal with heavy pedal pressure to duplicate a panic braking situation. The front and rear pressures should be different. Most manufacturers do not publish these pressures. The rear brakes usually are “shut” down between 500psi and 800psi, while the fronts can climb to well over 1500psi See Figures 49.5, 49.6, and 49.7).What you are looking for is whether the rear pressure has any limitation. If the rear pressure is over 1000psi and is close to or equal to the front pressure, then the valve is not working and will have to be replaced to correct the problem.

49.5

49.6

49.7

Proportioning Valves Rules of Thumb

Using the definition of the proportioning valve’s function and our understanding of system operation, we can use the following rules of thumb:

- On the front to rear split hydraulic systems, a failed proportioning valve should cause both rear wheels to lock up under panic braking – unless one rear brake has a condition that will prevent this (i.e., severely out of adjustment or seized wheel cylinder).

- On diagonal split hydraulic systems (FWD), it will be infrequent for both proportioning valves to fail simultaneously. If both rear wheels are locking under heavy to panic, look at mechanical causes before condemning the proportioning valves.

More Tips and Tricks

Want more tips and tricks? Consider joining our Facebook page “Mechanic Mafia.” Otherwise, check out some of our other articles by selecting the button below.

Facebook Group

More Articles