Here is to a new year in 2015. We hope you had a great 2014 and that your 2015 will be even better. We want to continue to help you with our Tech Trick Tuesday Blog posts and would love to hear from you on what you would like to learn about. This month, we will be covering brake hose service ideas and the do’s and don’ts of brake hose service.

Brake hoses are a highly misunderstood component of the brake system. There are many incorrect beliefs about brake hoses and even more incorrect service procedures done to them.

The following service and informational pictures along with their descriptive text will make you aware of some service and repair issues regarding flexible brake hoses.

Idea 1

Is this brake hose good or bad? Can it continue in service or not. You can’t fully diagnose the serviceability of a brake hose by its physical appearance. This hose may have an internal restriction or rust build up on the inside of the bracket. You need the full story of any brake problem to help in the analysis.

Idea 2

This front brake hose is obviously cracked but is it unserviceable? The general conscience in the aftermarket repair world is that if a brake hose is cracked the recommendation is that it should be replaces “soon” as it wouldn’t be getting any better. The outer layer of the hose protects the inner layers and cracks in themselves don’t dictate an immediate replacement as long as it’s only the outer layer that is cracked.

Idea 3

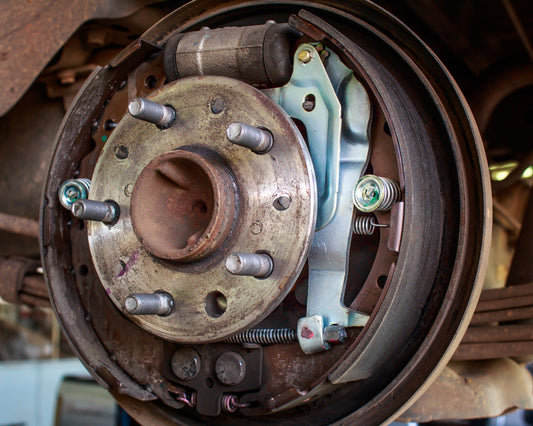

This vehicle has a pull. Is it caused by the brakes themselves or by a hose problem? In this case there is substantial rust and scale build up on the inside of the mounting bracket which is pinching the hose and decreasing its ability to move fluid. The vehicle is pulling to the side that has a non-restricted hose as that side receives more fluid when the brake pedal is applied.

Idea 4

To establish that it was mounting bracket rust build up issue the crimp on the bracket was opened up with a hammer and chisel. The vehicle then had a decreased brake pull. Hose replacement (both sides were replaced) solved the problem.

Idea 5

Never allow a caliper to hang by a brake hose. This is especially true if the hose is old and no longer as flexible as it was when new. If brittle enough or if it has been in service long enough the hose might actually separate from its crimped end if there is a sudden pulling force applied such as when a caliper falls from the upper control arm and is caught by the attached hose.

Idea 6

Heat is a prime enemy of brake hoses. If you use heat to free up a frozen flare nut on a steel brake line to flexible hose attachment point plan to replace the hose. If you heat the crimped end of a hose hot enough it will suddenly “explode” separating itself from the crimp. This will also spray very hot brake fluid all over the place.

You can read part 2 here.

We will have more of the story on checking for brake problems next week for Tech Tricks Tuesday.

You can also follow us on Social Media to know more of what we are up to and to get even more tips and tricks.